Technology has become an inescapable part of our lives. We can’t imagine getting by without technology in the present fast-moving world. When a business, socialization, and social propagation occur with globalization, we cannot survive without technological advancements. The primary reason that technology serves is communication. Web-based media and other technological applications have united families. Communication is needed in professional fields too, and technology guarantees that we can speak with the world from any place we are. Technology has helped a great deal in improving the rule of peace and law. Today we have telephone cameras, CCTV cameras. We have the PC and web to track down any criminal from anyplace with a worldwide information base.

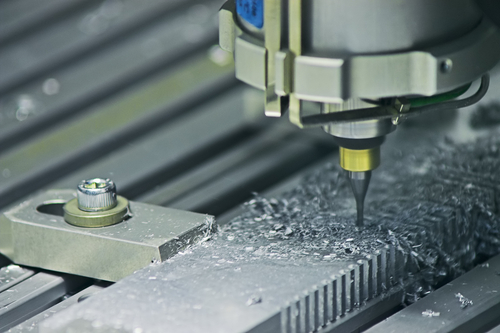

Technology has contributed immensely to the universe of entertainment. From video and PC games to TVs, a wide scope of technological innovations has assisted us in our leisure time. Indeed, even today, film watching is not, at this point, restricted to a theatre space. Online streaming platforms and applications are moving the entertainment world to a total digitization mode. Technology has impacted greatly on the industrial sector too. Complex manufacturing processes like press die casting became a lot simpler with the introduction of technology. Die casting is the manufacturing process that can produce complex metal parts through dies, a reusable mold.

Know all about die-casting

Die-casting is a manufacturing process used for casting metal items, including the constrained presentation of liquid metal into the mold cavities at extremely high pressure. Die There are different types of die casting.

Hot-Chamber Die Casting

Cold-Chamber Die Casting

Low-Pressure Die Casting

Vacuum Die Casting

Squeeze Die Casting

Semi-Solid Die Casting

Press die casting is the most popular type of die casting, and there are two variations for it: High pressure die casting and low-pressure die casting. Die casting has a lot of advantages. The parts and components produced are strong, durable, and dimensionally stable. It can give complex shapes within adjacent resilience compared to other production strategies. The use of machines is eliminated and, at the same time, with a high production rate. Die casting is much stronger than the usual plastic molds. The zinc casting, which is present in the die, offers great corrosion resistance. Die casting can produce smooth surfaces than other forms of casting. It can combine numerous capacities into one complex molded part.

Broadly about Press die casting

Press die casting is a rapid, reliable, and cost-effective production process for manufacturing metal components with high volume, which have high tolerances and are not shaped. The pressure die casting process comprises infusing a liquid metal composite into a steel shape under high pressure. After that, it cools down and solidifies quickly and from a net-shaped component, automatically extracted. Press die casting is comparatively cheaper than other casting processes. It provides castings with close dimensional standards and a very sleek surface finish. Castings are lighter in weight because they have thin walls. Press die casts can be very costly, and subsequently, they are done only for high-volume production.

Press die casting is the most effective and popular type of die casting, and the quality of the components produced is uncompromised.