In today’s printing world, it’s more common to hear SLS and SLA as they are widely used in the 3D printing sector. A lot of people are not familiar with these two terms except for those who are in the printing industry.

For those who are interested to know more about 3D printing services, you’ve come to the right place. In this post, we are going to briefly highlight everything you need to know about SLA printing.

What is SLA?

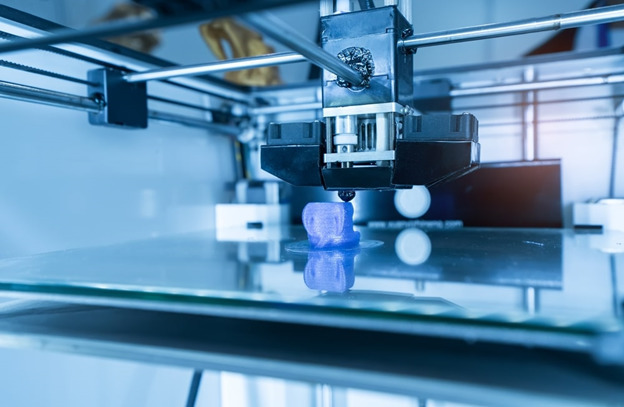

Before delving any deeper let’s first understand the definition of SLA. SLA means stereolithography; its regarded as one of the first 3D printing technologies to be ever developed, the tech was first introduced in the early ’80s and was later patented by 1984.

Inlay man’s time, the process entails the use of ultra-violet light in curing a polymer material. Te vat photopolymerization is a procedure whereby the liquid resin is cooled forming a hard plastic, the process is done layer by layer till the formation of a hard and solid object is achieved.

SLA is one of the most preferred 3D printing options by bot clients and manufacturers as it provides smooth surfaces and detailed prints.

Steps followed in SLA printing

There is a wide range of steps followed in SLA printing. The first and the most important step is having the product design at hand, the file format used in SLA has the same similarity as those used in 3D printers.

The only key difference between SLA and other 3D printers is the amount of heat required in the process especially in photopolymerization. Due to heat your part/product may have a bit of warping or deformation especially to the product design being worked on.

Designing plays a vital role in SLA printing, the design can be mitigated in several ways such as designing walls with a uniform thickness just to mention a few.

SLA printers can either have bottom-up or top-down orientation, but for most modern printers they use a bottom-up approach.

For the photopolymerization, it normally begins with the resin, followed by a mixture of monomers and oligomers.

When the resin is hit by the ultra-violet rays, it will provide sufficient energy for the separation of the monomer and oligomer.

After this, the curing process commences which is specifically done on the UV curing chamber for approximately two hours; another option is exposing it to direct sunlight for about one to two weeks.

Benefits of SLA printing

SLA comes with a myriad of benefits that includes:

- Objects/products created using SLA printing have smoother and natural finishing which can be quite impossible with other techniques such as FDM. SLA primarily uses fine-laser points to enable it to produce detailed and comprehensive designs.

When compared to FDM, SLA printing does a much superior job.

- SLA provides more diversity, printers will have a wide range of resins at their disposal which can be used to make specialized and customized parts/prototypes, the resin also is quite durable and have rubber-like traits. When using FDM’s, printers will not have such kind of luxury.

META: Have you wondered what SLA is all about? Well, in this post we have highlighted all the functionalities and methodologies associated with the printing tech.